| Sign In | Join Free | My howtoaddlikebutton.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My howtoaddlikebutton.com |

|

Warranty : 3 years

Customized support : OEM

Place of Origin : Jiangsu, China

Brand Name : NXF

Model Number : DN15-DN1500

Technics : Casting

Connection : Welding

Shape : Reducing

Head Code : Round

Product name : Monel 400 End Cap

Material : UNS N04400/NiCu30Fe/NA12/Nu13

Standard : UNS

OD : DN15-DN1500

Thickness : SCH5S-SCH80

Size : Customizable

Type : Welding

Brand : NXF

Packing : Wooden Case

MOQ : 1pc

MOQ : 10 pieces

Price : $5.00/pieces 10-99 pieces

item | value |

Technics | Casting |

Shape | Reducing |

Head Code | Round |

Place of Origin | China |

Jiangsu | |

Warranty | 3 years |

Customized support | OEM |

Brand Name | NXF |

Model Number | DN15-DN1500 |

Connection | Welding |

Product name | Monel 400 End Cap |

Material | UNS N04400/NiCu30Fe/NA12/Nu13 |

Standard | UNS |

OD | DN15-DN1500 |

Thickness | SCH5S-SCH80 |

Size | Customizable |

Type | Welding |

Brand | NXF |

Packing | Wooden Case |

MOQ | 1pc |

|

|

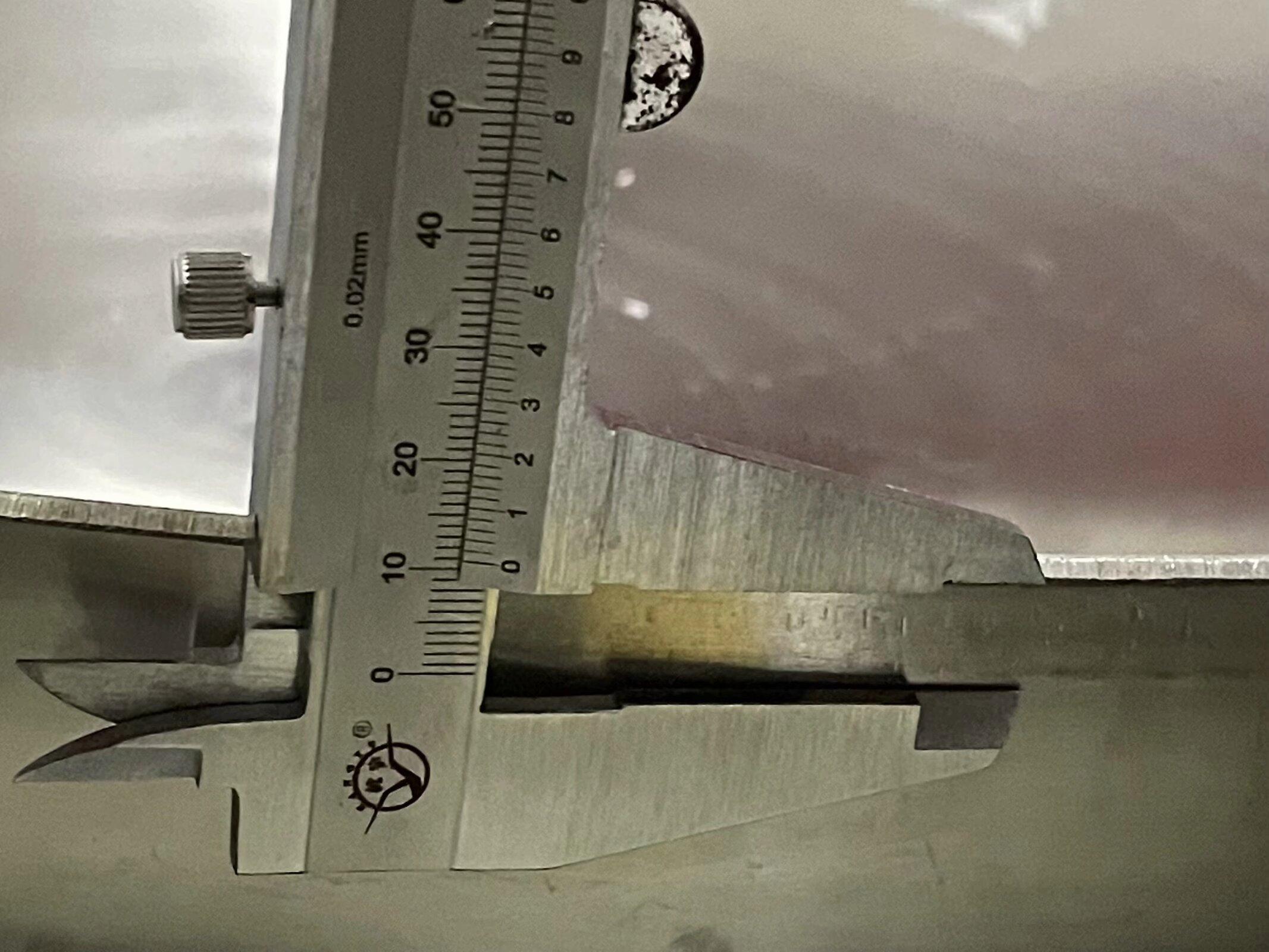

Monel 400 DN15-DN1500 SCH5S-SCH80 Customizable End Cap Pipe Fittings with Optimal Resistance to Stress Corrosion Cracking Images |